Flood Coolant System

This is a very simple flood system, low volume for now. I'm using a rectangular bucket from US Plastics for the sump. The pump is a 12vdc 500 GPH Tsunami from Walmart. I'm using 1/4 poly tubing and push-to-connect fittings mostly from Automation Direct. I'll change to a larger tube later when it's all enclosed to have more volume. Some Loc-line from Mcmaster Carr # 10095K11 for the nozzle. A few sink drain parts and pvc pipe drain the coolant into a strainer which is just an auto console item here with a filter screen from a pond pump system. Puts out plenty of coolant but doesn't make a big mess. The chip pan and enclosure will be added back sooner or later.

|

|

Loc-Line

|

|

|

|

Sump

|

|

|

|

Flood System

|

|

Click to Enlarge

Simple Way Covers

These are just some High-Strength EPDM Rubber sheet 1/16 x 6 #8985K322 from McMaster Carr to keep the chips off of the ways and ballscrews.

|

|

Way Covers 1

|

|

|

|

Way Covers 2

|

|

|

|

Way Covers 3

|

|

Click to Enlarge

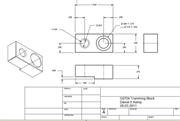

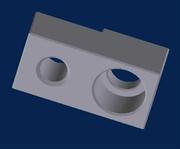

Tramming Aides

These are the Aides shown to us by machinechick on cnczone. They are something that came on her mill from Top Tech. You can use the setscrews to fine tune the head movement from side to side to tram in the X axis. Once set, lock the jam nuts. Next time you need to rotate the head, loosen the cap screws and pivot the aides out of the way. When you move the head back to vertical, pivot the aides back into position, tighten the cap screws and the head should be back in tram. Tighten up the head bolts and you're good to go.

|

|

g0704 tramming block

|

|

|

|

g0704 tramming block3d

|

|

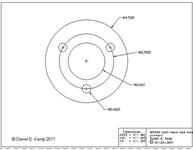

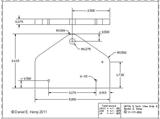

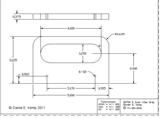

3 Bolt Head Mod

This mod also brought to us by machinechick adds greatly to the rigidity of the head. It's pretty simple, the holes don't have to be exact, about 15/32 inch.

I have a template below to help laying out the hole locations. Note: The 2 spare t-bolts that come with the mill can be used as is on newer shipments.

|

|

3 bolt head mod hole pattern

|

|

G0704 Tramming

Below are several videos to show how to square the column and tram the mill.

The first show a version of Rolliedads method for squaring the column, the last shows an alternate version using a precision square. I used this one from Shars.com, several other types are available like this Precision Cylinder Square.

G0704 Axis Calibration

This video shows how to use the Axis Calibration tool on the Mach 3 Settings page.

This will fine tune your Steps Per settting in your motor tuning so that when Mach 3 tells the axis to move a certain distance, it actually moves that distance. Compensates for leadscrew error, not as well as screw mapping though. The longer distance you test the better. Best to do this at several places along the axis and average the results. Remember after you are finished, go back and round the steps/per in Motor Tuning to the nearest full number, NO decimal places!

G0704 4th Axis

Made from a 6 inch Horiz/Vert rotary table from Wholesale Tool # 1990-0015

G0704 Optical Home/Limit Switch

My very compact home/limit switch using an Optek optical switch from Allied Electronics.

G0704 5th Axis

Made from a 6 inch Horiz/Vert rotary table from Wholesale Tool # 1990-0015

G0704 Economical Threadmilling

Using a tap ground down as a threadmilling cutter.

G0704 Vise Grip.

My version of an old shop jig to ease the lifting of a mill vise as seen here

for my 5 inch Shars Vise.

|

|

vise grip 1

|

|

|

|

vise grip 2

|

|

|

|

vise grip 3

|

|

|

|

5 inch vise grip 2

|

|

|

|

5 inch vise grip

|

|

G0704 ATC 4

The 4th Automatic Tool Changer I've built to date. This is a very compact unit that mounts on the end of the table but takes up very little of the tables workspace.

This is the smallest with a 6 tool TTS tool capacity. I have 2 other versions with 8 and 10 tool capacities.

It uses Tormachs TTS cnc version tool holders.

G0704 Power Drawbar 2

This is a more compact power drawbar than my previous version, this one is designed strictly for TTS use.

Floating type that puts no strain on the bearings.

Can be quickly removed to allow full quill usage.

Easy access to the drawbar for tension adjustment or R8 tool swapping.

Can provide 1500-2000+ lbs pull on the TTS tools depending on your air cylinder and air pressure.

Alternate simple leg and side support design provided.

Parts list and supplier part #'s also included.

You provide the air cylinder of your choice.

Search for Fabco on Ebay for good deals.

This pdf will help with the part#'s for cylinders including multi-stages.

Catalogue - Master Catalog - FABCO-AIR - (Version JPG) - page 109

If anyone is interested just shoot me a note at hoss@g0704.com for the download link and password.

G0704 Powder Coating Modestly

This video shows how I use my Craftsman Powder Coater, a toaster oven and a cardboard box to apply a very durable, long lasting and beautiful finish on some machined parts. I get most of my powders from Columbia Coatings.

.jpg)

.jpg)